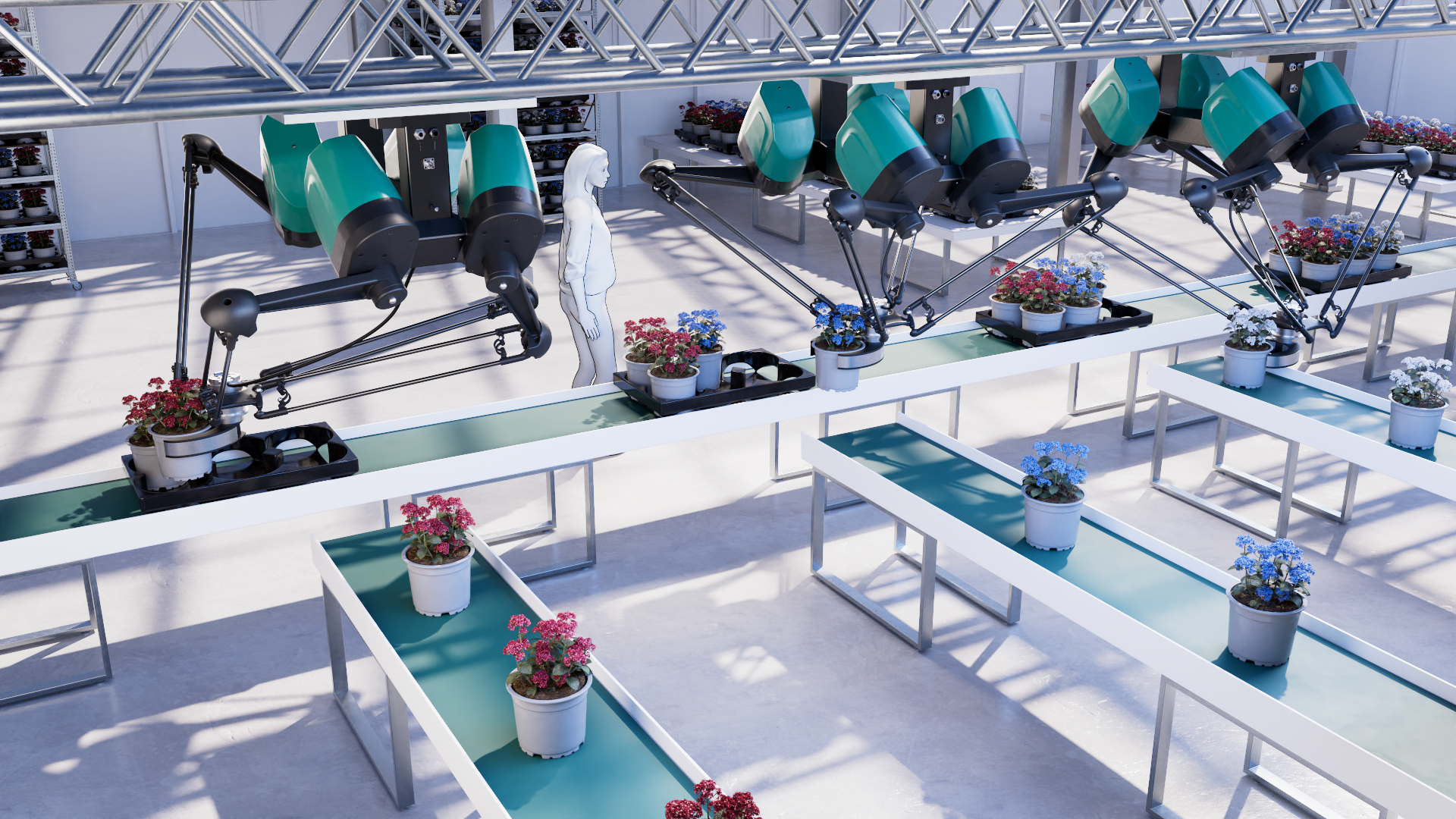

Pot to tray robot for fast, precise greenhouse automation

4XROBOTS’ delta cobots automate pot to tray placement with consistent spacing, speed, and flow — ideal for greenhouse growers scaling up production. Maximize throughput while reducing manual labor strain.

Why manual pot to tray placement holds you back

Manual tray loading slows your greenhouse down. It’s repetitive, error-prone, and physically demanding for your workforce. These problems make it hard to keep pace with high-mix production or seasonal scale-ups.

Challenges include:

- Inconsistent placement – Manual handling creates misaligned pots and inefficient tray usage

- Repetitive strain – Workers face fatigue and injuries from bending, lifting and loading

- Slow throughput – Manual workflows limit how fast you can move plants through production - it's harder to scale

How 4XROBOTS improves pot to tray workflows

Our pick-and-place delta cobots are built to deliver repeatable, high-speed automation with no fatigue or errors. Experience up to 4 times faster cycle times and superior plant placement quality:

- Consistent tray loading at high speed

- Reduces physical strain for greenhouse workers

- Compact design fits easily into existing production flow

What Is robotic pot to tray automation

Robotic pot-to-tray automation uses high-speed pick-and-place robots to load potted plants into trays with consistent spacing and alignment. It's ideal for greenhouse operations looking to:

- Improve productivity without increasing labor costs

- Ensure uniform plant quality and placement

- Scale operations with reliable pick-and-place robotics

Customer case story

No video selected

Select a video type in the sidebar.

Ready to explore our cobots in detail?

See how 4XROBOTS delivers fast, precise, and scalable pick-and-place automation fort pot-to-tray workflows. Check out technical specs, layout options, and integration examples.