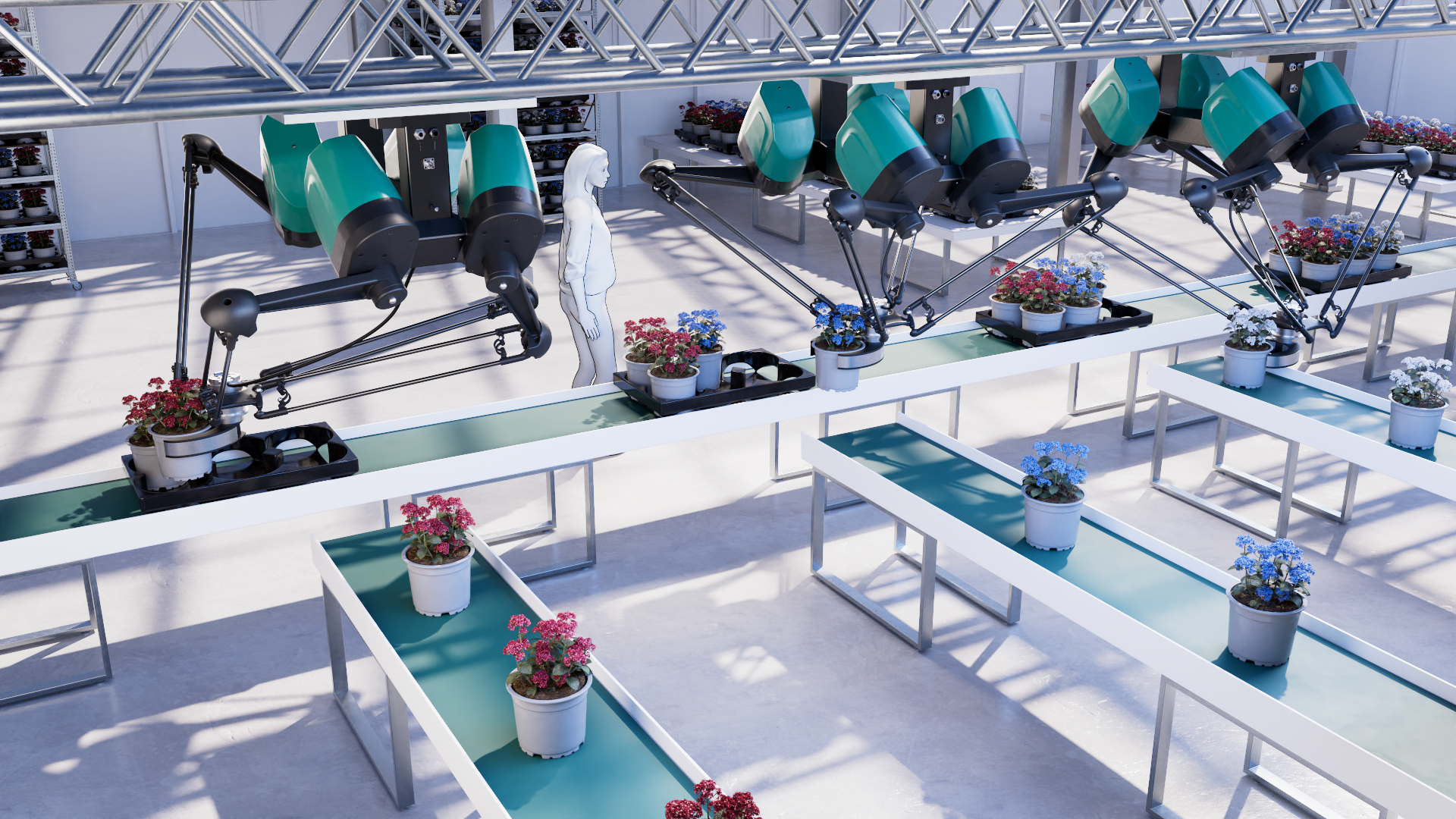

Meet the 4X collaborative delta robot

- Fast, Flexible Pick & Place Automation

Engineered for high-speed collaborative solutions, our collaborative robot (cobot) delivers precision placement for transplanting, packing, and more - all with a compact, mobile footprint.

Speed That Boosts Throughput

Complete repetitive tasks faster with up to 1000 mm/s / 3.3 ft/s speed - optimized for high-volume pick & place automation.

- Handles up to 2400 picks/hour (application dependent)

- Reduces production bottlenecks and idle time

- Consistent cycle times with no drift or fatigue

Built for Flexibility

Compact and lightweight, the 4X Delta Cobot adapts to shifting production needs across different applications and layouts.

- Weighs just 35 kg / 77 lbs— move it with ease

- Modular design integrates into small or large setups

- Suitable for transplanting, pot-to-tray, and packaging

Easy Setup, Fast ROI

From unboxing to operation in 2-3 days - reducing deployment time, integration cost, and IT involvement.

- No complex programming or coding needed

- IP-rated and ready for harsh environments

- Fits within existing workflows with minimal disruption

Safe to Work With, Certified to Standards

Designed for collaborative workspaces and certified to global safety standards for peace of mind in daily operations.

- EN ISO 10218-1 and ISO/TS 15066 compliant

- Safe to operate next to human workers

- Quiet (<70 dB), clean, and workplace-friendly

Product specifications

- Collaborative Speed: 1000 mm/s

- Pick Rate: Up to 2400 picks per hour (application dependent)

- Payload (Rated): 1 kg

- Number of Axes: 3

- IP Rating: Minimum IP54

- Operational Temperature Range: 0 to 45°C

- Humidity Range: Maximum 90% (non-condensing)

- Noise Level: Under 75 dB(A)

- Robot Weight: 35 kg

- Safety Standards: EN ISO 10218-1 and EN ISO 13849-1

- Workspace: 1,200 x 800 x 550 mm (application dependent)

Easy installation with minimal interruptions

- Keep operations running: Manual tasks can continue during setup, with minimal impact on daily workflows.

- Overhead mounting: The robot fits above conveyor belts to preserve valuable floor space.

- Same footprint, more output: Automation is added without the need to redesign your layout.

- Quick on-site installation: Fully installed and operational in just 2–3 days at your facility.

Safe by design – Built to work alongside people

- Automatic safety stop: The robot instantly pauses movement when it senses contact or obstruction.

- Soft, lightweight construction: Minimizes impact and risk if accidental contact occurs.

- No fencing required: Enables true collaboration between people and robots in the same workspace.

- Collaborative by nature: Lets growers stay close to their crops and continue working safely while automation handles repetitive tasks.

- Smart safety software: Continuously monitors motion and surroundings for safe, reliable performance in real production environments.

Transplanting Automation

Help your crops grow faster and more evenly with reliable, high-speed transplanting - no more manual handling or damaged seedlings.

-

Better spacing = better harvest

-

Gentle handling reduces transplant shock

-

Up to 400% faster than manual workflows

Root Extraction

Automate root separation without compromising plant health. Our cobots handle each plug with precision from the Moving Gutter System (MGS) or any other tray - even in dense trays or delicate media.

-

Gentle yet firm extraction, reducing damage

-

Consistent timing improves batch processing

-

Frees up skilled labor for more valuable tasks

Pot to Tray Transport

Eliminate repetitive placement and save hours per day. Perfect tray accuracy and seamless integration with your existing greenhouse flow.

-

Precision tray loading with minimal setup

-

Flexible handling of different pot sizes

-

Reduces strain injuries from manual repetition